Safety

Our approach to safety is built on the personal responsibility every BNSF team member brings for themselves, their colleagues, communities and our customers’ freight.

BNSF trained 4.5K+ employees at TTC, 14.5K+ in the field and 500+ rail industry employees.

A Foundation of Training

We have a robust multi-layered approach when it comes to safety training. While we have formal programs driven by technical rules, rail industry recommendations and federal regulations, we also have BNSF-specific training initiatives developed and conducted by employees themselves. Additionally, at the BNSF Technical Training Center (TTC) in Overland Park, Kansas, BNSF employees take courses and simulate the safe operation of locomotives, cranes, crossing gates and other important equipment.

Our Safety Vision

The BNSF safety vision is to operate free of accidents and injuries.

Celebrating Safety

Every year, BNSF recognizes employees in several departments who are helping our company move toward our safety vision by naming them as Safety Employees of the Year.

Key considerations for the award:

Demonstrating leadership in safety programs

Promoting safety through innovative ideas

Proactively identifying risks

Reinforcing safe behaviors with positive feedback

2019 Safety Employees of the Year include:

Wylie Baker

Intermodal Safety Employee of the Year

Intermodal Equipment Operator & Safety Instructor, Seattle

Thomas Dodge

Engineering-Structures Safety Employee of the Year

Bridge Foreman and Safety Facilitator, San Bernardino, California

Kendrick Gallien

Engineering-Signal & Network Control Systems Safety Employee of the Year

Signal Maintainer, Rosenberg, Texas

Patrick McClelland

Mechanical Safety Employee of the Year

Carman & Safety Assistant, Newton, Kansas

Mario Rubio

Transportation Safety Employee of the Year

Locomotive Engineer, Clovis, New Mexico

"As a leader, I try to give and build confidence in others. If you treat people with respect and show them that you care, you build good morale – and get great outcomes. It comes down to paying attention and listening. Plus, I never give up on the one person who might be negative. If you’re persistent about building a relationship, eventually, they come along."

– Kendrick Gallien

"Being a safety leader is not always easy. You have to practice what you preach. We all have the right to work in a safe environment, so as a leader, I try to listen, to educate and to find the right way to talk to co-workers. If they have questions, I may not have the answer – but I’ll make sure I get one."– Mario Rubio

Safety Bells

For 20 years, BNSF has been recognizing the teams that achieve the lowest reportable injury-frequency ratios with Safety Bell Awards. These coveted awards – the actual brass bells once rung by locomotive crews of BNSF predecessor railways – are proudly displayed in the winning locations. Recognition also includes celebrations with BNSF leadership and lapel pins to commemorate each team’s commitment to safety.

2019 Safety Bell Winners

Division: Kansas Division

Transportation: Kansas Division

Mechanical: Kansas Division (Zone 4),

Lincoln, Nebraska, Diesel Shop & Commerce, California, Shop

Engineering: Heartland Division

Hazmat Response Training & Resources

To optimize safety, BNSF has established a network of more than 180 hazardous materials responders and advisors trained to handle everything from small non-accident releases to major releases. Strategically placed emergency response equipment at more than 60 locations across our network supports a responder’s ability to react quickly and effectively.

Through the Transportation Community Awareness and Emergency Response (TRANSCAER) program, BNSF, along with other rail industry partners, provides training for emergency hazmat responders.

With our special mobile classroom, BNSF directly delivers high-quality hazmat training to first responders across our network. The classroom, a modified boxcar, provides theater-style seating for up to 37 and is accompanied by a training tank car fitted with the various valves used on different tank car types. Every year, the mobile classroom brings hands-on training to municipalities and saves them the cost of having responders travel.

Another vital resource for first responders is the AskRail app. Developed by the rail industry, this app enables responders to immediately access information about a train and the hazardous materials it may be carrying.

BNSF helped train 6.8K first responders to deal with hazmat emergencies.

Fire-Fighting Trains

BNSF routinely stages tank cars full of water in areas on our network that are prone to wildfire. In Washington state, where dry, hot weather conditions and large undeveloped areas of brush and grass can combine to create prime conditions for wildfires, we have deployed two special trains devoted to helping fight fires.

The Pasco Fire-Fighting Train

2 tank cars with 30K gallons of water

1 fire car with aqueous fire-fighting foam

1 caboose command center with generator to power emergency equipment

The Wishram Fire-Fighting Train

3 tank cars with generators, pipes and pump systems

Caboose command center with spray bar and water cannon

These trains allow BNSF to fight fires near track ourselves or to work with local firefighters. Firefighters can board the caboose at designated access points and BNSF crews then move the train to the fire, often in areas fire trucks can’t easily access.

The average fire truck holds about 500 gallons of water; BNSF tank cars carry 30,000 gallons each.

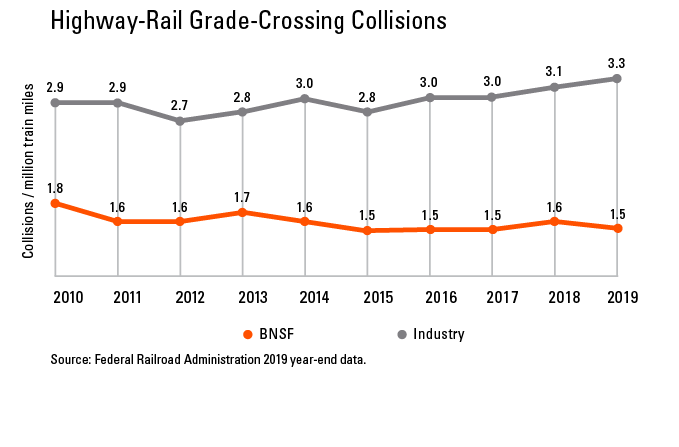

Grade-Crossing Safety

BNSF has one of the lowest highway-railroad grade-crossing collision rates in the industry. One powerful factor in lowering the rate of collisions is to close grade crossings altogether. Working with communities and landowners, BNSF has closed more than 6,400 grade crossings since 2000. In addition, we participate in public safety programs such as International Level Crossing Awareness Day in communities across our network.

Positive Train Control

BNSF leads the North American freight rail industry in the implementation of Positive Train Control (PTC), a federally mandated safety system. With PTC infrastructure installed on our network and beyond the federal mandate in certain locations, we are now focused on interoperability with the other railroads that operate across our PTC-equipped lines.

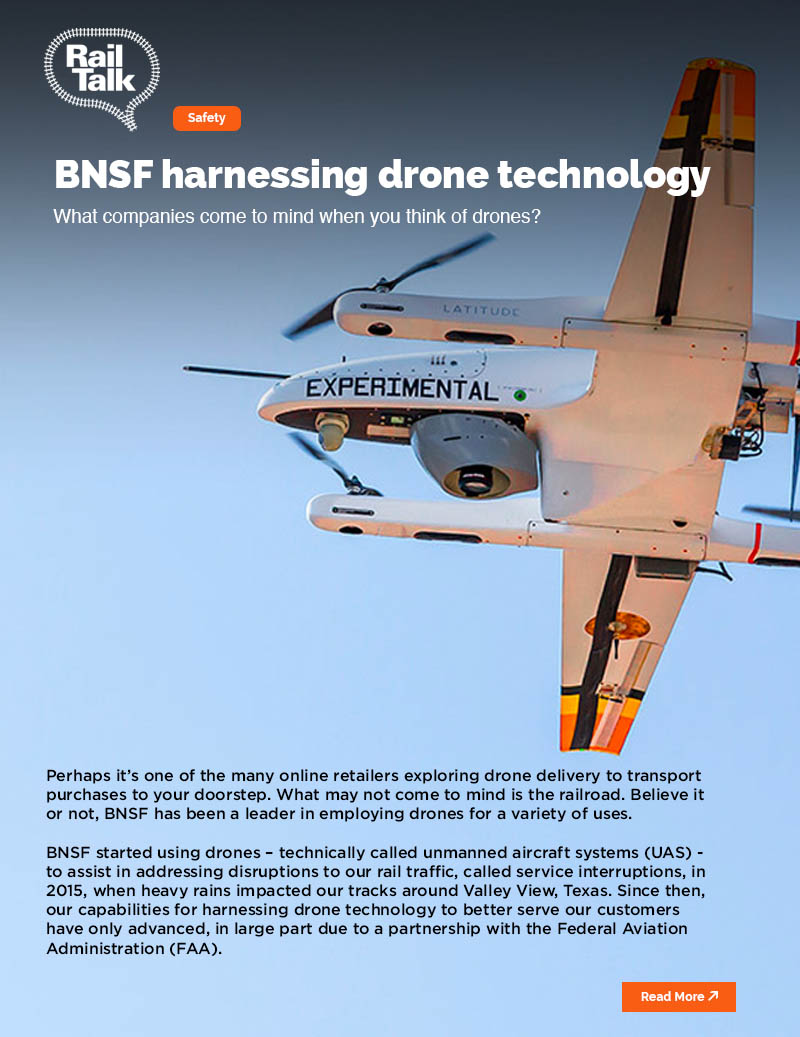

Rigorous Inspections

BNSF regularly conducts extensive track, bridge, rail and weather event inspections across our network, meeting all federal requirements. BNSF uses a combination of instrument-equipped rail cars and trucks, bridge inspection vehicles, unmanned aerial vehicles and specially trained inspectors. Tools include autonomous track measurement systems, ultrasound for internal rail inspections, ground-penetrating radar, high-definition cameras and accelerometers to analyze roadbed, track and bridges.

Safety-Enhancing Technology

BNSF leverages technology to continuously improve safety. Machine Vision Systems (MVS) are a recent example.

MVS technology combines digital images of rail car components with sophisticated data analysis to identify defects before they lead to larger issues, such as equipment failure or a derailment. Our MVS is now using artificial intelligence (AI) models to teach machines how to identify potential defects through images. Leveraging AI helps us immediately take corrective actions, enabling us to safely transport the goods our customers and communities need every day.

Machine vision systems across BNSF's network capture 750K wheel images per day, which we analyze to detect possible defects.